Product classification

- Thermal spraying -

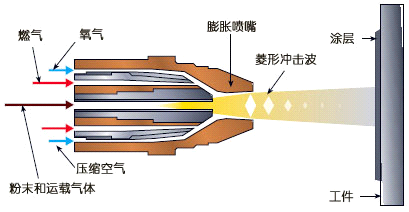

Supersonic flame spraying

Supersonic flame spraying uses the principle of rocket engine, using aviation kerosene as fuel, pure oxygen as combustion agent, and forms a combustible mixture after high-performance atomization to form high-temperature and high-pressure gas, which is accelerated to supersonic flame flow through the Laval nozzle. The flight speed of coating material particles plays an important role in the performance of the coating, when the particles hit the surface of the substrate, high speed can form a huge impulse, the deformation ability of the particles is strong, which is conducive to the formation of high adhesion and high density coating. The bond strength of the commonly used WC-12 Co coating was tested, and the results showed that its bond strength was ≥ 70Mpa.

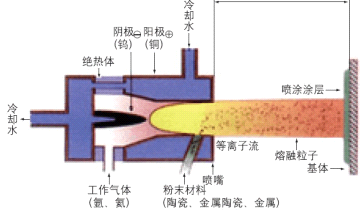

Plasma spraying

Plasma spraying is the most flexible of all thermal spray processes, and it is able to reach enough temperature to melt any material, so the variety of coating materials that can be used is almost unlimited. Plasma spray guns consist of small chambers consisting of a cathode (electrode) and an anode (nozzle). The gas passes through the chamber while being broken down by high-intensity arc to form plasma substances, and releases a large amount of heat, and its temperature can reach 6000 °C ~ 16000 °C. When the coating material is ejected into the gas flame at high speed, it melts and is pushed towards the target base layer.